Key Consideration For Choosing The Right Cnc Machine Tools

CNC Machine tools are the heart and soul of every machinist shop. This is why choosing the right tools to equip your shop can make or break your business. There are many considerations before concluding on what and what not to buy. From price to product quality, availability of spare parts, aftersales support, and future returns on investment (ROI), we take a look at the key considerations for selecting the right CNC tools.

• Begin with cost

Cost is the top consideration for any business. However, cost cannot be the primary driver for investing in machine tools. CNC machine tools will often be fair, premium-grade, or cheap. The differences in these grades of machines will be reflected in lifespan, strength, durability, and wear and tear. Consider the size of your CNC machine and the manufacturer grade of tools that should be used with it. Factors such as force, torque, and pressure of the machine can indicate whether the chosen tool will work properly or optimally. Avoid purchasing cheap and brittle tools as they might break or deform under the operating conditions or pressure.

In the case of premium tool manufacturers to highly rated alternatives, cost can be a driving factor. If you are familiar with a brand that can deliver dependable quality, you may choose to save cost by going for this tool over premium brand name alternatives.

• Manufacturing quality

Next, place considerations around the performance of the machine tool when manufacturing is considered. High-grade tools have some level of performance, rigidity, and durability. Low-cost machine tools may not hold up well during crashes and cause further damage to the main CNC machine. Asides from rigidity, low-cost or inferior quality tools are likely to be unable to deliver the precision and accuracy required for most CNC machine operations. Therefore, the ability to provide quality parts with high precision is a key consideration ahead of pricing. Finally, check for tighter tolerances in your machine tool as this is often an indicator of better lifespan.

• Availability of spare parts / warranty

Evaluate the machine tool and consider how easily you can obtain replacement parts, servicing, product warranty, and even aftersales support. The speed and availability of replacement parts, product warranty claims, and manufacturer response can all contribute to reduced or prolonged downtimes in the event of a problem with the machine tool. This is why you need to buy CNC machine tools that are very available on the market with genuine spares and aftermarket support.

• Safety is key

Safety is not one of the first things that come to mind when choosing CNC machine tools. However, safety is a crucial aspect of every equipment. Whenever and wherever you can, ensure that you incline into tools with more safety incorporated into their design. This is usually more common in costlier machine tools. As there is no price to the safety of the machinist and workshop, protecting your operators and customers can help you drill down insurance costs and conform to better safety standards in your workshop.

• Tool changer design

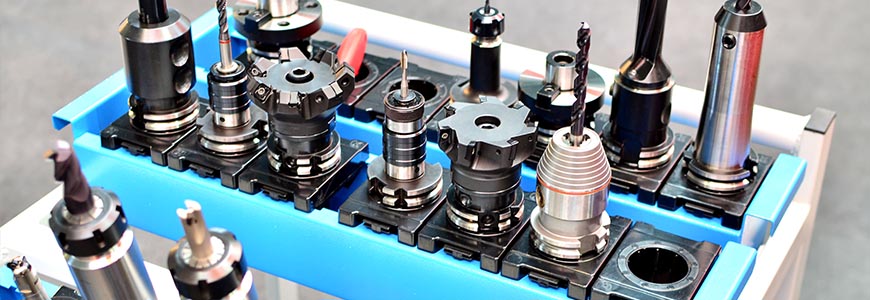

Consider the tool holder and tool changer layout. Consider how it works and the ease of replacement, the accessibility of the tools during operation, and the extent of difficulty in replacing or cleaning broken tools, chips and debris.

• Power and capacity

Refrain from investing in spindles with low-power and low-quality motors that cannot match the required speeds or become fatigued after small hours of operations. Rather, opt for high-power spindles that have large bearings and a slower rate of wear or tear. Generally, the higher the horsepower rating, the more efficient the machine cuts rigid materials. Cheap, belt-power spindles will also fail during high-power applications and may become unstable from vibrations. This can result in defects and errors in machining the workpiece. This is why the machine capacity, speed, and power are some of the most important parameters in choosing a machine tool. High power spindles will generally deliver better RPM, resulting in faster operations, longer tool life, and overall cost savings.

Premium Parts CNC prototyping in China

Approaching CNC tool selection from a strategic planning perspective is important if you’re getting it right with your workshop and manufacturing hubs. Before concluding on the tool, you must consider ease of use, safety, cost, availability of parts, functionality, physical and cosmetic properties. At Premium Parts, we offer excellent CNC machining and rapid prototyping services in China. Get in touch with us to review your new project and get a free quote.